What is a hydroentangled nonwoven?

In this article, we talk about the base material of wipes and look at the types of fibres found in wipes.

When you take out a pack of wipes with you and unpack them, you get a bunch of fabric pieces that look like tissue paper but feel softer than paper towels. Stretch it and you’ll find that it’s still flexible, doesn’t tear easily, doesn’t shatter when you pull it unlike paper towels, and will wipe away stains much easier than paper towels.

Just when you’re about to fold it up to fight laziness and are about to throw it in the toilet, no good, better find a bin to throw it in or your toilet will clog up!

The unbreakable, stubborn fabric mentioned above with good absorbency, elasticity, softness and strength is what we call SPUN-LACE: the non-woven most commonly used in wet wipes.

I’m sure you have some idea of what a spunlace is, but here I’d still like to give a detailed insight into it.

1. Definition of hydroentanglement: What is a hydroentangled nonwoven?

A good understanding of spunlace, you need to know what is a non-woven fabric, because spunlace is an important type of non-woven fabric, non-woven fabric called non-woven, is composed of oriented or random fibres, is a new generation of environmentally friendly materials, because of the appearance of cloth and certain properties and called cloth, with moisture, breathable, flexible, light, non-combustible, easy to decompose, non-toxic non-irritating, colourful, inexpensive, recyclable and other characteristics, such as the use of polypropylene (pp material) granular material as raw material, by high temperature melting, spouting, laying outline, hot press rolled continuous one-step production.

The hydroentanglement process, on the other hand, is a non-woven fabric manufacturing system that produces a hydrodynamic effect by continuous jets of high-pressure water, under which the aligned fibres begin to surge, shift and rearrange themselves, and become entangled with each other, and this entanglement is irregular, achieving a reinforcing effect and thus providing fabric integrity.

In short, hydroentanglement is

- Composite of different fibres

- A type of nonwoven fabric based on its manufacturing technology.

Hydroentangled nonwovens are made by spraying a high-pressure micro-fine water jet onto one or more layers of fibres, so that the fibres become entangled with each other and the web is reinforced and has a certain strength, the resulting fabric is a hydroentangled nonwoven.

2. Characteristics of hydroentangled nonwovens

- Flexible entanglement, does not affect the original characteristics of the fibres and does not damage them

- Appearance closer to traditional textiles than other non-woven materials

- High strength, low pilling

- High moisture absorption, fast moisture absorption

- Good breathability

- Soft hand feel and good drapability

- No need for adhesive reinforcement

3. Process flow of spunlace nonwovens

Fibre placement → Pre-opening → Fine opening → Mixing → Pre-feeding → Carding → Spreading → Drafting → Hydroentanglement → Drying → Slitting → Winding → Storage

4. Typical fibre types for wet wipes hydroentanglement

- Polyester (PET) and polypropylene (PP).

PET, scientifically known as polyethylene terephthalate, commonly known as polyester resin, is a resin material, milky white or light yellow highly crystalline polymer, currently the largest variety of synthetic fibres. It has high strength and elastic recovery, good wrinkle resistance and conformability, as well as good heat resistance, water and oil absorption, and is robust and durable.

PP, scientifically known as polypropylene, is a polymer made from propylene through a polymerisation reaction, transparent and light in appearance, the lightest of the commonly used resins, non-biodegradable, light in weight but high in strength, excellent in abrasion resistance and elastic recovery, better than most fibres in terms of chemical resistance, and antibacterial, safe and hygienic.

They are widely used in the production of wet wipes and are known for having good strength.

- Viscose and Tencel

Both types of fibre are made from wood or bamboo pulp, extracted from natural wood cellulose and reshaping the fibre molecules to obtain cellulose fibres. They naturally have good absorption and strength properties and are known for their softness, freshness, breathability, anti-static, UV resistance, good fastness to dyeing and biodegradability to meet the needs of human skin and they are often used in applications to prevent skin irritation.

- Wood pulp

Wood pulp fibre is a fibre made from wood pulp, but it is different from ordinary vegetable fibres. It is a secondary fibre, a product separated from the raw wood fibre and is mostly used in the textile sector. Because it is mainly extracted from wood pulp, we call it wood pulp fibre and the main types are softwood and hardwood; they are 3 mm and 1 mm in length respectively. They have a high surface area and a flat ribbon form, which gives them good cleaning properties. They also have high liquid absorption, but the disadvantage is their poor strength, but in the new biodegradable wash-off wipes this has become a great advantage.

- Cotton

The fibre length of cotton varies considerably with each seed, from 3 mm to 30 mm. Compared to viscose, it has better absorbency and water absorption, but it does not have the same softness. Thanks to its flat, ribbon-like surface, cotton is known for its good cleaning properties.

The most common hydroentangled fibre combination used in wet wipes applications is PET + VISCOSE. In fact, with the current developments in hydroentangled nonwovens technology, we have adopted a number of new hydroentangled techniques for the production of wood pulp hydroentangled fabrics, which are becoming increasingly popular and are seen as alternatives to some common hydroentangled fabrics, which come in two types.

Wood pulp + PET and wood pulp + PP, these wood pulp nonwovens are more economical as an alternative base material for spunlace wipes.

Look for the right blend and you will find that it is very rare to find wipes made from just one type of fibre. Due to the different properties of the fibres, they are blended together in different proportions depending on the situation at hand. Household wipes need more absorbency and strength than softness.

5. Types of fibres used in the new wipes

- Biodegradable wipes

Biodegradable wipes contain viscose fibre, bamboo fibre and polyester fibre, etc. At present, the mainstream wipes on the market are 30% viscose fibre + 70% polyester fibre, but also contain 100% viscose material biodegradable wipes, which can be biodegraded in the natural environment without causing pressure on the environment.

- Flushable Wipes

Some flushable wipes are made of 100% wood pulp, or they can be made of wood pulp and viscose, which can be dissolved in water and flushed directly down the toilet in a non-woven fabric, so you don’t have to worry about clogging to achieve the flushable wipe effect.

- Both biodegradable and flushable wipes.

A sustainable product, consisting of viscose and wood pulp fibres, the legacy product of a sewage treatment system can be a useful soil amendment rather than just becoming landfill material in a landfill, making it a popular wet wipe on the market.

Cost is of course another factor to consider. Fibres like wood pulp, viscose and Tencel can be expensive, resulting in biodegradable flushable wipes being relatively more expensive than regular wipes.

6.Types of patterns for hydroentanglement

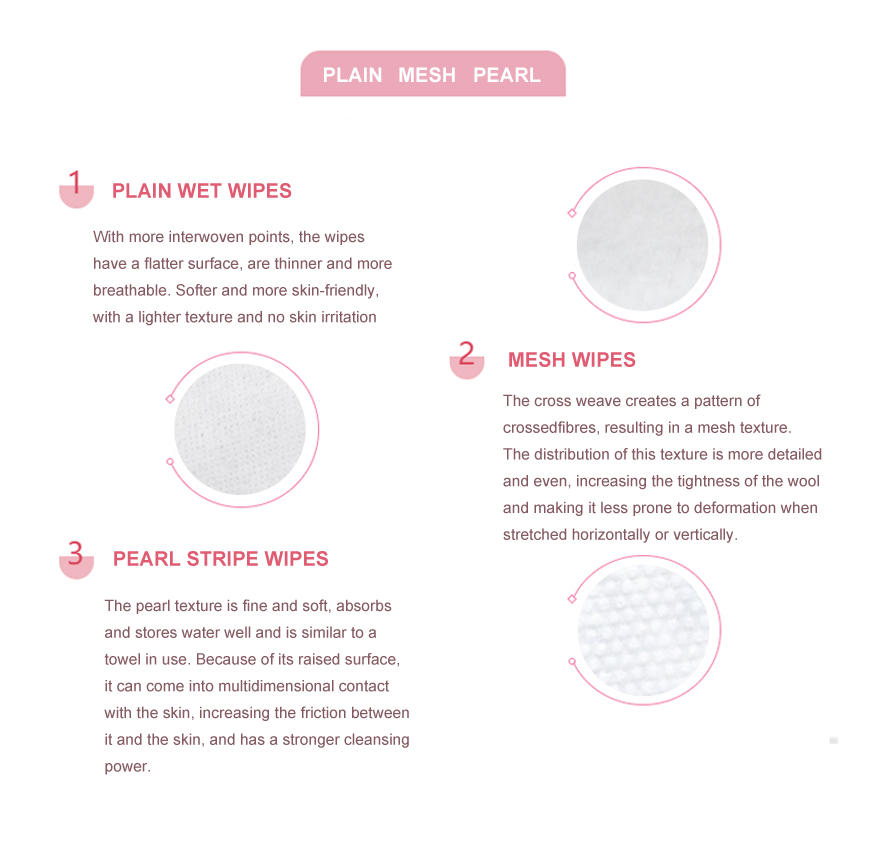

There are 3 common patterns found in the hydroentangled fabrics of wet wipes.

- Plain weave

More interweaving points, flat product surface, lighter and more breathable. It is softer and more skin-friendly, with a lighter texture and no irritation, so plain weave is more common and widely accepted in the wet wipes market.

- Pearl (embossed)

Pearl grain texture is delicate and soft, and has a good effect of absorbing and storing water, and is similar to a towel in use. Because of the raised surface, it can make multi-dimensional contact with the facial skin, increasing the friction between it and the skin, and the cleaning power is stronger. Compared to the plain pattern, the pearl embossed pattern is more beautiful, so it costs more.

- Mesh

Plain patterns are more common and widely accepted in the wet wipes market. Which pattern you choose depends on your preference and consumer acceptance, although the pearl embossed pattern does make the wipes look prettier and therefore cost more.